3D printing is great, but not for everyone

[ad_1]

Even though 3D printing was predicted to be a lot more common than it has turned out to be, the technologies is nevertheless going through massive advancement. Senior Researcher David Bue is in charge of creating DTU’s big ‘3D printing playground’, where by new records for miniature printing are presently currently being set.

3D printer – illustrative image. Impression credit score: lppicture through Pixabay, absolutely free license

Anything can be printed – from backyard gnomes to pizzas – and we will all quickly have a 3D printer at property, enabling us to produce whatsoever we want. This was the media’s prediction right after the initial 3D printing patents expired in 2009 and the printers turned cheap enough for regular folks to get hold of a person.

But as you know, items did not function out that way. Not the very least for the reason that this assertion did not make perception – really couple people today can draw the object they want to print on a computer system, which is the first move in 3D printing.

“No, 3D printing did not turn out to be an industrial revolution as predicted somewhat, it has been an evolution. But the technological know-how is however acquiring in specified exclusive niches and is now the next fastest escalating know-how globally,” claims David Bue Pedersen.

He is a senior researcher at DTU and probably the particular person in Denmark who is aware of the most about 3D printing. He was the very first to comprehensive a PhD on the issue back in 2012, and he has considering that set up a flourishing study natural environment at DTU.

Immediately after the hoopla

David receives aggravated considering about the vastly inflated expectations for 3D printing. Thus, he has selected to differentiate himself from the initial hype all over the technologies and concentration his study on the industrial application, which in complex phrases is named ‘additive manufacturing’. He talks enthusiastically about the technology’s fantastic prospective:

“It’s amazingly simple to 3D print really sophisticated parts that would be extremely complicated to make conventionally,” he starts.

For example, gasoline turbines for the aviation sector have to be able to cope with particularly substantial combustion temperatures. This usually means you want to construct them in more durable and much better resources, which are also significantly additional hard to get the job done. On a 3D printer, you can develop up your workpiece to approximately the remaining geometry, and then you just have to complete it off with a diamond resource.

You can furthermore steer clear of a cumbersome casting approach involving a good deal of handwork if you 3D print individually equipped hearing aids. And little parts such as the hearing aids’ audio channels, which are easily clogged with earwax, may well even be printed with cilia to make them self-cleansing.

Metal objects, ordinarily built of titanium, can also be printed with porous surfaces that, for instance, allow bone to ‘grow into’ implants these types of as artificial hips, producing it attainable to keep away from the glue that in some circumstances has confirmed problematic.

Openness drives engineering development

You can purchase bigger or more compact 3D printers on the market place, but in accordance to David, it is not significantly different from shopping for an inkjet printer: It can only do a single issue, the know-how is locked, and you are dependent on the supplier. The market as a complete is extremely closed, which hampers innovation and maintains artificially higher charges. David would like just the reverse.

“We want to open the black box and look at the know-how from a holistic approach, the place we can dive into all the specifics and their interactions and transform them as necessary,” he claims.

In 2019, the Poul Thanks Jensen Foundation granted DKK 21.3 million to the Open up Additive Production initiative. And an aged casting hangar is now currently being transformed into a 3D playground in which David and his workforce can examine and produce all sorts of metal and plastic prints. The ceiling is 9 metres substantial, and a single of the laboratories will be housed in a tower created from outdated transport containers.

“We want to develop an innovation atmosphere that can encourage all the young DTU skills to further the use of 3D printing in Denmark,” he claims.

David describes himself as a multi-artist with a wide understanding of all the numerous distinctive subjects required to understand 3D-printing technological know-how e.g. building, personal computer science, physics, chemistry, and elements and production engineering. And he has collected 25 scientists and learners with a deep understanding of just about every their subject matter for his team.

“They make a terrific group and perform seamlessly alongside one another there is no silo research, for the reason that it is precisely in the interfaces that magic transpires. I am happy to be in a position to equip these youthful and enthusiastic persons with a solid toolbox in additive production just before they are let free in the field or where ever else they conclusion up. It added benefits both equally exploration and industry – and without a doubt culture as a full.”

“I’m just an engineer”

David started at DTU in 2003, when there was more flexibility of preference in planning his Master’s degree than below the recent curriculum. He wished to know as a lot as attainable about as several topics as possible, so he entered all the special programs he could.

“My education and learning doesn’t have a direction, I’m just an engineer,” as he places it.

Right before joining DTU, he was a qualified method developer at Microsoft, and in his spare time he fixed vintage cars and motorcycles.

“I was passionate about both of those and could have ended up just about anyplace inside procedure developing. From beet harvesters to airplanes, I could have engaged 100 per cent in it all. I was just very inquisitive and fascinated by technology, and I couldn’t get sufficient of making devices and being familiar with how they’re built and how they perform,” he smiles.

But he finished up doing a PhD in 3D printing and subsequently agreed with his boss that DTU could likely push this area even further. Given that then, the laboratory has ongoing to develop, and a large element of the equipment has ended up in the corridors. From there it will now quickly move into the new hangar. The researchers have crafted all the devices in completely open up buildings. Every depth is documented and can consequently be modulated depending on how they are used.

Miniature plastic print history

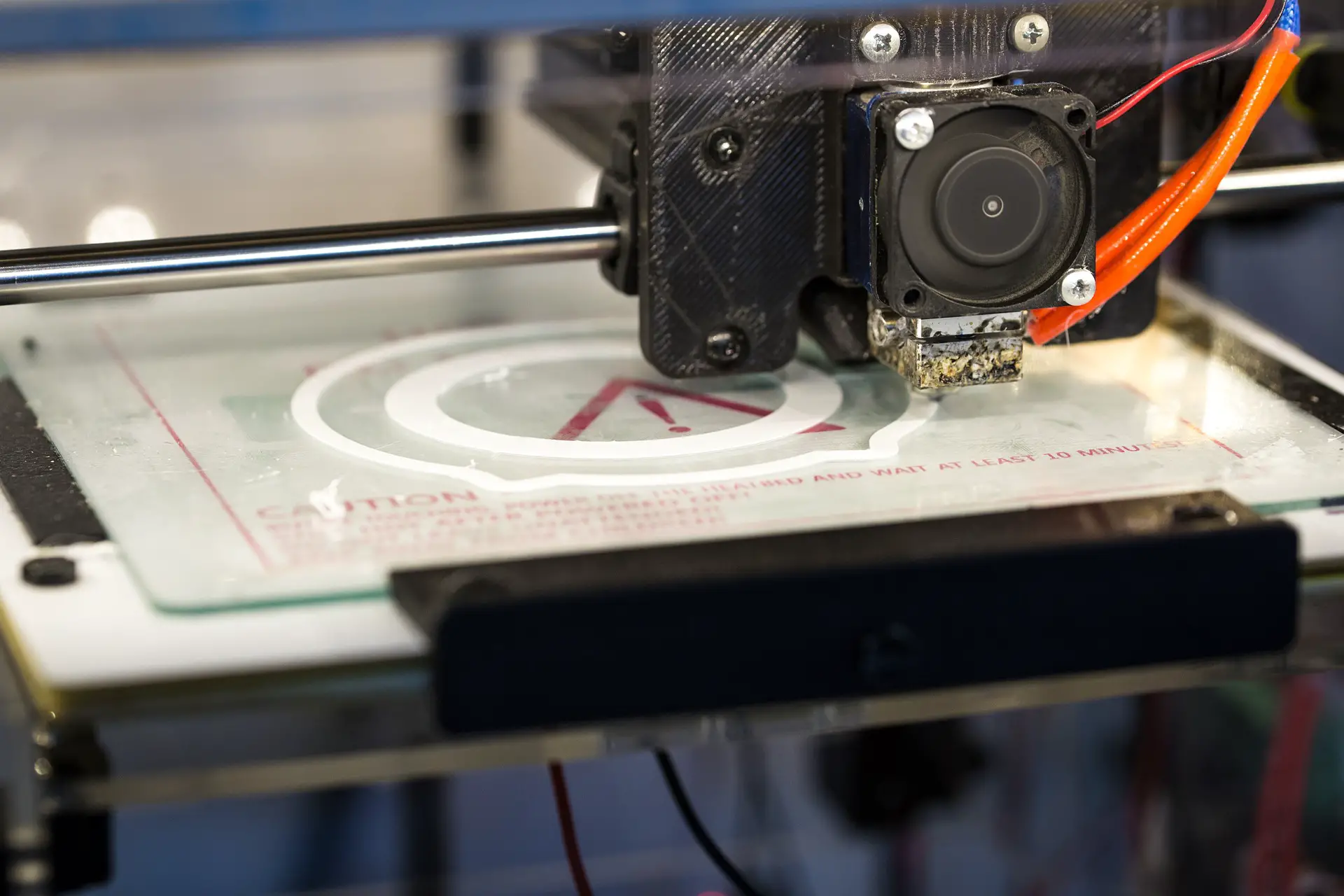

You print in steel by pulling a powder as fine as flour throughout a wallboard, scanning it with a laser and therefore welding it together into a stable material. The laboratory’s metallic printer can weld at incredibly large speeds, and the scientists are acquiring the gradation of metal alloys with distinctive functions. They also have products to observe the approach and detect any welding defects as they manifest, and to analyze the concluded materials. Listed here, for the very first time in the background of the entire world, it has been feasible to print the well known Damascus steel, which is utilized for, e.g., kitchen area knives.

In the moist lab, researchers get the job done with liquid plastic like the form applied for dental fillings. The objects are developed layer by layer, which are steadily hardened working with a UV light. David’s team also designed this products from scratch, and three PhD college students recently set a new report when they printed a plastic figure working with a print answer that can be measured in microns, which has not been found right before. David challenged them to downsize even even further, and immediately after some recoding, they ended up in a position to current the very same determine with particulars smaller sized than a micron.

“My objective is to demonstrate what could take place if producers established 3D technologies cost-free, enabling potential buyers to enhance on distinctive parameters in its place of just urgent the start button. And I enable Danish corporations undertake 3D printing and consequently streamline production,” David summarizes.

Pleasurable, but not just for pleasurable

A focused 3D-printing fanatic have to also very own a 3D printer.

“Yes, at 1 stage I experienced involving six and 8 printers in the basement. But now there’s just an outdated Puch Maxi moped that I mess around with a bit. I have all the printing gear I can aspiration of in the lab.”

And what does the skilled himself print?

“Certainly not yard gnomes and ladles. It’s much much easier to receive these from Ikea or Diy centres. I’ve typically carried out custom upgrades for my 3D printer, so I didn’t have to have them produced in a workshop,” he says and concludes:

“When the man who researches 3D printing does not use 3D printers at household, it speaks volumes about the technologies. If you buy a massive, pricey printer for DKK 15 million and absolutely acquire it apart, you will obtain just about no printed features in it. So 3D printing is not as universally relevant as it was predicted to be. But it’s fantastic for a large amount of specialized tasks.”

Source: DTU

[ad_2]

Source backlink As technology continues to impact the way in which we live and conduct our everyday activities, 3D printing has evolved from being a simple curiosity to a legitimate tool for creating various complex objects. Indeed, this manufacturing process, which sees raw materials used to create three-dimensional objects via a computer-designed file, can be incredibly useful for businesses or hobbyists alike.

However, it must be acknowledged that 3D printing is not suitable for everyone. First and foremost, the technology is still relatively expensive; the cost of the printer itself is likely to run into the thousands of dollars. Furthermore, the materials used to craft the printed item can be relatively costly in the long run; while the initial cost is fairly low, the cost can rise significantly with more complex builds.

Additionally, 3D printing can be relatively difficult to learn. Users should be versed in digital modelling and have a robust understanding of 3-dimensional shapes, as well as the properties of thermoplastics, metals, and other materials that are commonly used for 3D printing. If these skills are not possessed, it can be difficult for an individual to successfully create their desired object.

Finally, 3D printing is not the most reliable technology. There can be errors when printing smaller and more complex items, which can be incredibly frustrating and may result in the need to start from scratch.

In conclusion, 3D printing is an incredibly popular and powerful tool; however, it should not be assumed that it is suitable for every user. The initial cost of the machinery, materials, and the learning curve associated with the technology, as well as its unreliability, means that 3D printing is not suitable for everyone.